Bormey srl Among The First 35 Newly-Constituted Medium-Sized Enterprises In Cuba, Exported 5,000 Peanut Bars To Italy. Is United States Next? U.S. Department Of State Regulations Would Approve.

/Granma

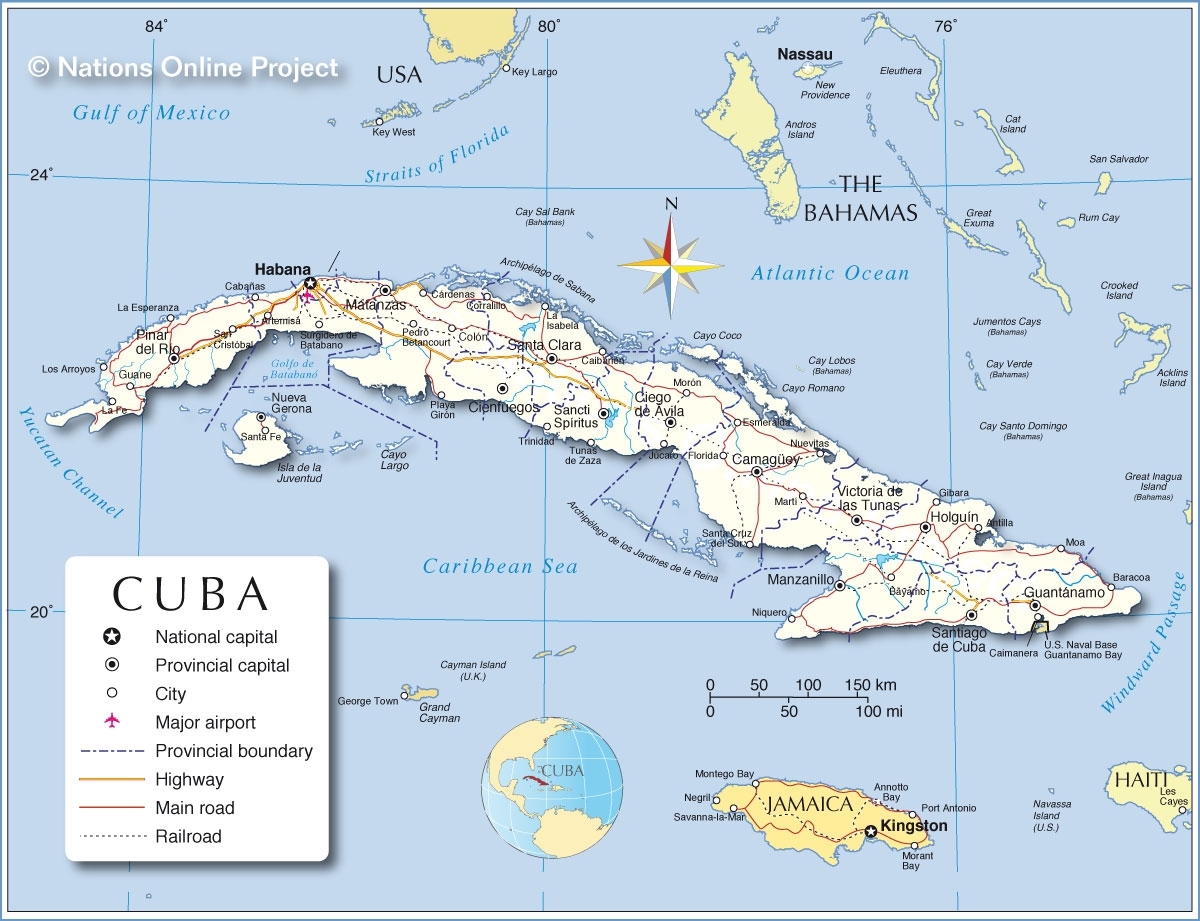

Havana, Republic of Cuba

25 October 2021

Micro, small and medium-sized enterprises moving Cuba forward

Micro, small and medium-sized enterprises are now a reality in Cuba, a real possibility encouraged by the state to strengthen the country’s development of the country with its own resources

Authors: Julio Martínez Molina and Ángel Freddy Pérez Cabrera

The creation of micro, small and medium-sized enterprises (MSME) are now a reality in Cuba, an option encouraged by the state to strengthen the country’s development with oue own resources.

Open since September 20, the call to register these businesses gives prevalence to activities such as food production, goods and services exports, local development, circular economy and recycling, science, technology and innovation, to which manufacturing and computer science services have been recently added. Experts believe that the constitution of these figures lead to a more flexible restructuring of the national economy, closer to the production activity and services of each territory in Cuba.

Alexander Brito Brito, president of the Cienfuegos branch of the National Association of Economists and Accountants of Cuba, thinks that the MSMEs nurtures from the economic environment of the territories by the emergence of new entities that will have an horizontal relationship. “It will favor productive chains and it will reinforce the strategic design of development. Likewise, it will promote the consolidation of part of the state sector that seeks higher productive levels and efficiency in their processes,” he added. He pointed out that the private actor now earns the level of entrepreneur because they are running a business with new responsibilities and obligations and, as part of its growth, it can go from micro to small to medium enterprise and have an impact at the national level.

NATIONAL OPPORTUNITY FOR LOCAL PROGRESS

In the province of Cienfuegos, for example, 245 self-employed workers and three local development projects with potential to transition to MSMEs or Non-Agricultural Cooperatives (NAC) have been identified. At the same time, assessments are being conducted of some state enterprises.

A business dedicated to the maintenance of green areas, SERVIMAV (Green Areas Maintenance Service), is the first MSME approved in the province, in the municipality of Palmira. “We immediately saw the opportunity to begin with an activity with high demand in the territory,” said Andrés Guerra Monzón, senior partner of this micro business.

He explained that the services of the enterprise (comprised of two partners and an expected personnel of 12 workers) will include the pruning and cutting down of trees, mowing and manual cutting of the lawn, waste collection and transportation and it will provide these services to sport fields, children parks, docks and airports, among others. “Once we have established, we will begin to look for possible clients such as the Power Company, Communal Services, Highway Maintenance Services, Radiocuba, among others,” Guerra Monzón added.

The advantages of the MSMEs made Osiel Gil Falcón, partner at the Numancia Carpenter’s Workshop, in Cienfuegos, to take the step of becoming a micro enterprise. Two mini-industries for fruit and vegetable processing (from the municipalities of Lajas and Aguada de Pasajeros), and Jovero Verde tourist office, in Cumanayagua, are weighing the benefits of becoming MSMEs. Yainelys González Menéndez, expert on Local Development Projects, said there are several incentives for the rest of the economic actors:

-The tax on earnings of only 15 %

-Sales tax of only 5 %

-Prices of goods and services are set by agreement among the parties

-No custom taxes for the import of equipment and technology

-Access to bank credits in freely convertible currency is available

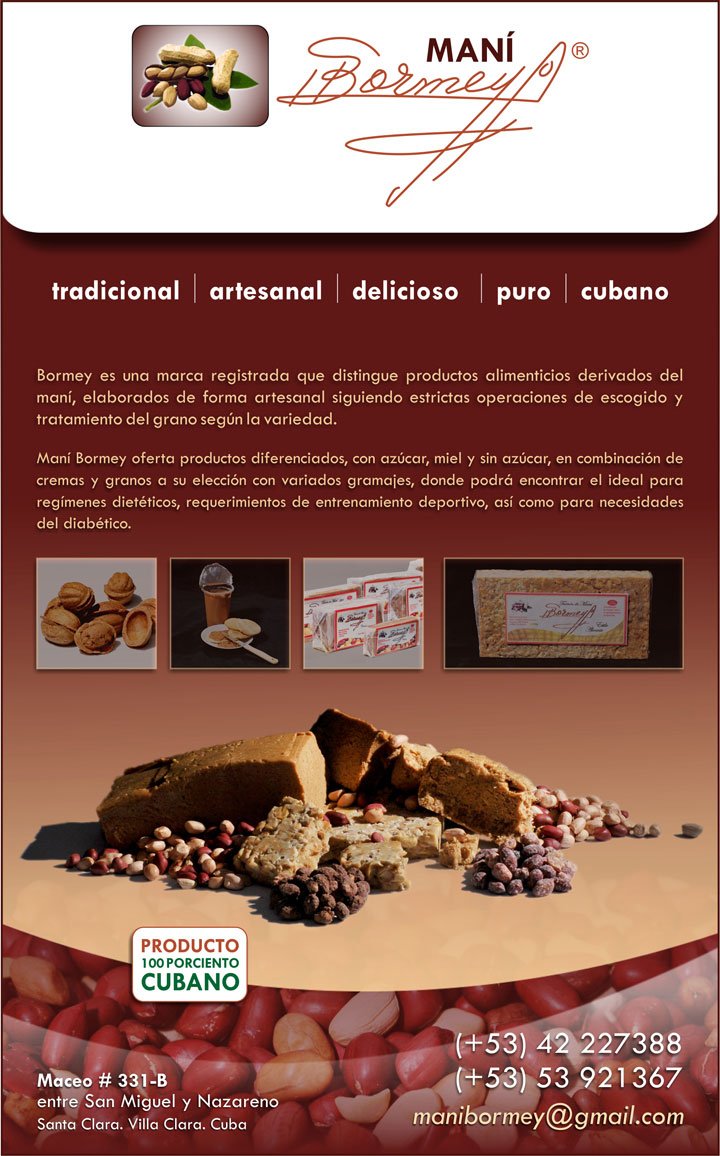

Young entrepreneur Orelvis Bormey Torres never imagined that his idea to conquer the popular favor with a product like peanut would impose the way it did for the pleasure of thousands of people both in Cuba and abroad who prefer the taste of the various products created by him. His passion for that grain comes from the crib. His grandparents and parents used to make a living cultivating peanut among other crops in his hometown Quemado de Güines, where they used to make exquisite turrones. Later on, when Orelvis was a student at the Marta Abreu Central University of Las Villas (UCLV), he transformed that family passion into a source of income and started to make his own sweets in 2004.

That is how the idea of The house of peanut in Santa Clara came to life. The quality of this brand, with a 100 % Cuban product, goes beyond the national market and it has even gathered a following in the United States, Italy, Canada and Germany, among other countries. With such credentials and the first successful export of 5,000 bars of peanut to Italy last year, the approval of his business as one of the first 35 MSMEs has come to help Bormey’s dream of expanding his thriving business and appeal to other markets in Cuba and abroad.

The young industrial engineer, who runs a business that manufactures over 30 products, including turrones, grains, candies and confectionery, all based on the oilseed and other nuts and processed fruits, describes this step as transcendental for the individual and the country’s economy. “Becoming the medium-sized enterprise Bormey srl means that we now have legal personality which allows us to celebrate contracts both for the purchase of consumables and for the export to other parts of the country and abroad,” said the young man, who also speaks of the demand to optimize the quality in all processes.

The measure, he expressed, has been definite in the lifting of the hurdles that slowed down the development of the project and also give the business credit advantages derived from a better determination of the corporate assets of the enterprise. Another benefit is that they can enter contracts with the farmers who supply the raw material, and to whom they can pay in either national currency or freely convertible currency, once the exports have been made since they would be in conditions to buy consumables that will help them make their state grow.

For that purpose, he requested around one hundred hectares of land to the Agriculture Ministry. In that extension of land, he could harvest, in two crops a year, the 150 tons of peanut he needs to keep the level of production, the new entrepreneur explained, aware of the importance of the partnership with the farmers in Encrucijada and Quemado de Güines, main producers of the grain in Villa Clara.

This business has also made him established links with the UCLV, specifically the Interface Society, to manage and take part in the development of varieties of fruits and grains of higher quality and yield. He also has working ties with the Research Institute of the Food Industry, the Center for Fishing Research and its certified laboratory, the Territorial Office of Normalization and Vegetable Health, among others, with which he has negotiated at the institutional level. Convinced of the success lying ahead, he emphasizes, “If Bormey succeeds, the mediu-sized enterprises succeed too, and the province and the country, in another way to move Cuba forward.”

IN CONTEXT

-The Ministry of Economy and Planning has received over 550 requests to establish MSMEs.

-None has been declined thus far.

-Some 102 MSMEs and two non-agricultural cooperatives have been approved.

-In Cuba there are more than 2,000 state enterprises and more than 600,000 self-employed workers, 52,000 of which hire personnel and over 5,000 have more than three employees.

-The tendency is for self-employed workers to organize an MSME or cooperative.

-Given the impact of the pandemic, many self-employed workers have modified their activities.

- Only Cuban citizens residing in Cuba may establish a MSME or cooperative. (Translated by ESTI)

LINK To United States Department Of State Self-Employed From The Republic Of Cuba Import Regulations

Havana Times

Managua, Nicaragua

15 May 2014

Cuba: Turning Peanuts into a Thriving Small Business

By Alejandro Ulloa (Progreso Weekly)

HAVANA TIMES — “What I have done is to start the business, use professional tools and take advantage of the opportunities presented by ‘the opening’ and the institutions, in order to develop an enterprise,” explains Orelvis Bormey Torres.

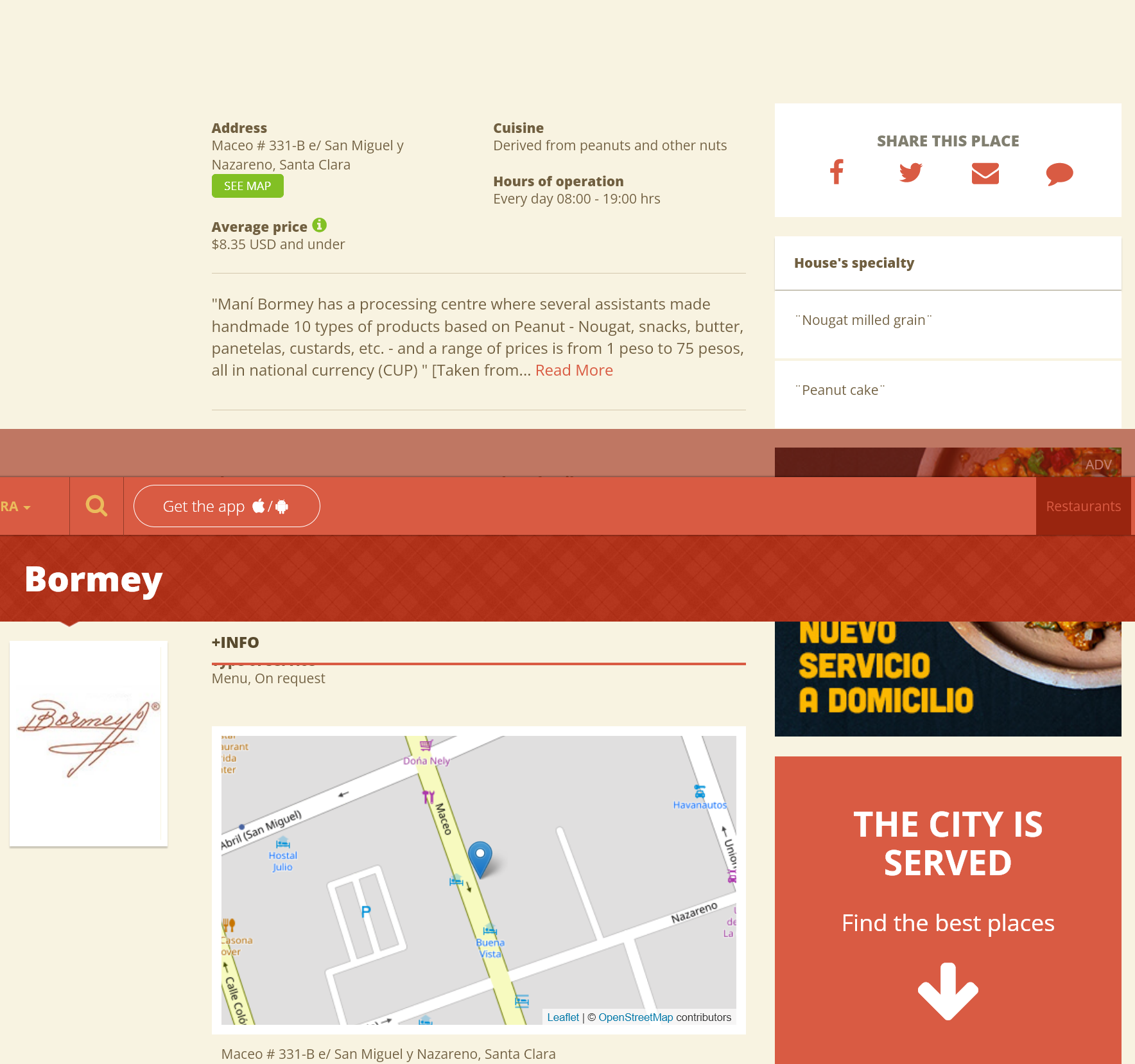

An industrial engineer with a Master’s degree, Orelvis a man just over 30, has created a brand (by now well known) and a prosperous business in Santa Clara, using peanuts as the basic product. Orelvis Bormey Torres says 300 clients show up daily at the Bormey House of Peanuts.

About 300 customers show up daily at the “Bormey House of Peanuts,” where he sells 21 types of turrones [nougat, fudge], five varieties of panetelas [a form of pound cake] and about 10 varieties of snacks [small bags of peanuts.) Ten years ago, that was unthinkable. “I always saw my grandparents and my father growing peanuts in Quemado de Güines, where I was born,” he says. “They also processed them into nougat.”

After his second year at the Las Villas Central University (UCLV), Orelvis turned that family tradition into a source of income. Two years later, in 2004, he himself began to make turrones. For about eight years, he worked with only one kind of dough and a single style of nougat. After he opened his House of Peanuts in December 2012, he worked with four kinds of dough (with sugar, without sugar, with honey and in Alicante style) and nearly 10 varieties of products. [Translator’s Note: Turrones originated in the Spanish region of Alicante in the 15th Century.]

“After I graduated, I kept raising peanuts, even though I was working for the State. I made the bars and took them once a week to the homes of clients I knew. My clientele later expanded. Of course, I never announced that I was selling peanuts because at the time no licenses were issued [to entrepreneurs]. Selling turrones was illegal, even though the sugar came from the store and the peanuts from my father’s farm.”

While selling turrones “on the sly,” between 2005 and 2012, the young engineer was the head of the purchasing department at the university where he studied and supervised product quality and human resources in companies like Caracol, a construction firm in Caibarién, and the Villa Clara Graphics Enterprise. The seven years of experience he acquired he now utilizes for his own business.

“I devoted the entire year of 2013 to putting together the manufacture and sale of the products that distinguish and represent my brand. For the rest of 2014 and the coming years, I will organize the procurement of raw materials. I didn’t ignore this aspect of the business but first I needed to set up a portfolio of products with stability, with a consolidated image.”

The Bormey House of Peanuts

It all started with the brand. “I always liked the way my father signed his name and — beyond the Bormey family pride — I tried to mollify the old man, who didn’t want me to quit my job. I asked him to sign his name, we designed the logo, and I went to Havana to register the brand at the Cuban Trademarks Office (OCPI). At that time, I owed about 20,000 or 25,000 pesos.” [over $1,000 USD]

By December 2012, the business had become serious enough for Orelvis to launch his House of Peanuts, which today has eight salaried workers (five factory workers and three salespeople) and retains the services of a designer and an attorney and has contractual relations with several state-owned companies.

After opening “the little house,” the Bormeys began to label each product in a different fashion, according to the rules. “We followed the procedures dictated by the Public Health Dept. for the handling of foodstuffs, the recommendations of the Food Industries Department and had the advice of the UCLV’s School of Agriculture regarding the grain that we buy. Their latest suggestion was that we should say on our labels that our products have no food preservatives.”

“We have been going ahead without finding any problems, without plans for improvement, but considering where the deficiencies are and taking steps to eliminate them.”

The price structure of Bormey Peanuts is very local. “We are in Villa Clara, whose prices do not compare with those in Havana. That’s why we set them using the production cost and adding a profit margin that results in a sales price — in national pesos [CUP] — that is accessible to our clients. Comparatively speaking, our prices are above the average for Santa Clara.”

An entrepreneurial vision

Fifteen months after the factory started operations, the labels that once said “Made by Orelvis Bormey” now say “Made by the Bormey Group.” To Orelvis, to keep his business going, he needs two basic premises: a good relationship with his workers and with the state-owned institutions, companies and suppliers. “We are not a cooperative or a state-run business, but we’re not just Orelvis. We are a group of people intent on transforming the image of the Cuban peanut, from a paper cucurucho [funnel] to a portfolio of products. That way, each worker receives the credit he or she deserves and feels more committed” to the job.

Referring to the company’s expansion, “something that opened the doors for us was the creation of an account at the Bank of Credit and Services of Santa Clara,” he says. This enabled the firm to sign contracts with state-run companies that print the labels, promotions and bags or sell cups, cake boxes and storage labels. Last year, the Chamber of Commerce invited the Bormey House of Peanuts to participate in the Havana International Fair (FIHAV-2013).

To Orelvis and his group of peanut vendors (who do not sell peanut bags on the street), it is vital to have a good chain of suppliers. “They are the main link to minimize costs,” he says. Some people buy peanuts from the farmers, store it and then, after the harvest is over, sell it at a price higher than normal. Bromey does not always buy from intermediaries but does depend on them for part of the year. He has invested about 10,000 CUP [$500] in storage containers alone.

“In order to maintain the quality of the product, improve its presentation and maintain its variety to reach the most buyers, we need to organize the flow of raw materials. I have to deal with the farmers to shorten the [production] chain, and increase their profits and mine. Not to mention the intermediaries, who are necessary.”

“I turned to peanuts because you can process them and preserve them without the need for special conditions. Also, the potential for its cultivation in Cuba is great, because of the propitious climate, the type of earth, the availability of seeds and professional support, because [peanut farming] can eliminate imports and generate jobs.”

Everything has to work just right, starting from the furrows. “A good harvest means that, once the peanuts have been extracted, they’re left to dry on the field, then harvested, separated from the plant, sun dried to remove the moisture and kill any fungus, and stored away. When ready to process, a machine shells them, removes the skin, blows it away. Then I grind them and mix them with sugar. I do this by myself, because the uniqueness of the Bormey products depends on that.”

Orelvis has been doing this in the same supply house for the past 10 years. “My supplier has two mills, one for the peanuts, the other for the sugar, and a mixer that other manufacturers use. But I give him the most business. So, once a week I process the peanuts we’re going to use.”

We asked: Wouldn’t it be better to own those machines and not depend on anyone? “No. The machines are not expensive but I would have to find a space for them, transportation for the peanuts, and all that to use [the mills] once a week. Where I do it now, it’s strategic for me. The man has a license and guarantees the necessary hygienic conditions. His capacity for processing suits my needs. It works and I don’t have to start a cooperative or change my routine.”

Later, in another supply house, there is space for the storage of dough and the manufacture of the turrones, ice cream, panetelas and other products. “Now that we’re in the business, we’re going to use the tools we learned in our training and our own experience to keep making a quality product that is recognized by our clientele. We are proud of our product and our brand.”

Orelvis Bormey’s peanut candy project has become a medium-sized enterprise. Photo: Freddy Pérez Cabrera