On 28 July 2021, the Ministry of Finances and Prices of the Republic of Cuba reported individuals subject to Republic of Cuba jurisdiction would be authorized to import, importantly absent tariffs and fees, photovoltaic systems and parts for non-commercial use. LINK To Official Notice The resolution states that the individual is responsible the installation of the photovoltaic system and its maintenance. The photovoltaic system must be compatible with and be connected to the national grid.

Granma

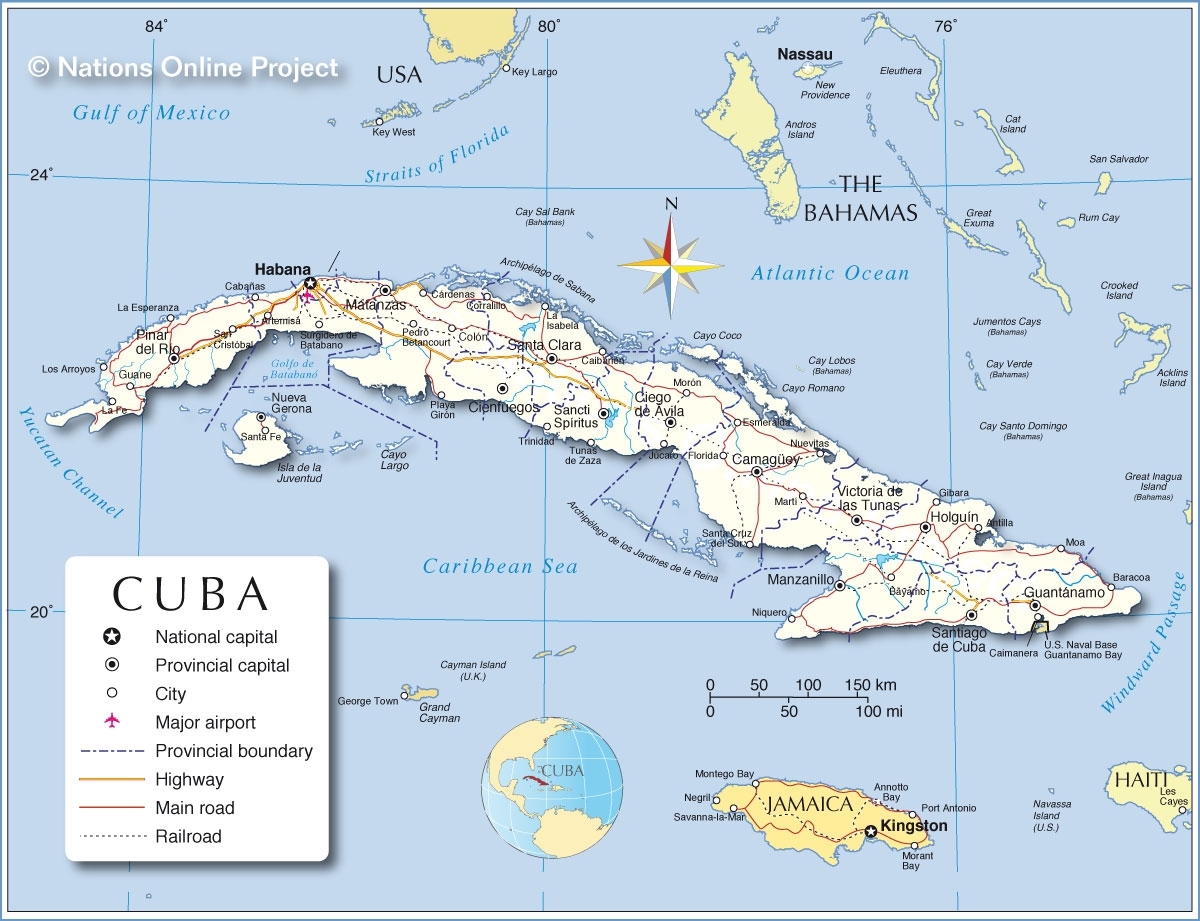

Havana, Republic of Cuba

4 November 2021

Starting today, Copextel will commercialize solar PV systems with 1 kW injection into the electricity grid for the residential sector. Although the service is expected to be extended to the rest of the country in the coming months, at this point it will only be sold in the capital, according to Tribuna de La Habana. The customer can go in person or call the Copextel call center at 7833-3333; In either case, the system will be automatically reserved until a technician visits it, within seven calendar days, to assess requirements that ensure the proper functioning of the equipment. The customer can make the purchase by electronic payment or by requesting a credit in a banking institution. The cost of 55,000 pesos includes all system components as well as their transportation and technician visits for installation and assembly. After that, the buyer must go to the electricity company and conclude the contract to connect the national electrical system. Among the requirements: available ceiling (ceiling) or floor surface 12.5 square meters, from concrete (panel); If it is soil, it must be paved (cement or asphalt) and exposed to the sun all year round. It shall be located, preferably, horizontally or, failing that, in such a way as to allow the settlement of the solar PV system. LINK To Video: https://www.youtube.com/watch?v=06uuP2yc0-0

Prensa Latina News Agency

Havana, Republic of Cuba

4 November 2021

Cuba furthers renewable energy uses for domestic market

Havana, Nov 4 (Prensa Latina) Cuba promotes the use of renewable energies for the residential sector of photovoltaic solar systems for its CUP commercialization, as announced by the state-run company Copextel. These systems use solar panels and inverters that help convert available solar energy into electricity for consumption at homes, businesses and industries, generating significant savings for the electricity bill, the Ecosol Power Division Manager Rolando Gómez told Cubadebate. The devices allow users to cogenerate electricity or inject energy in parallel, either for self-consumption or for dispatch to the National Electric Power System, Gómez added. Copextel company will be responsible for commercializing photovoltaic solar systems to the residential sector from November 4, thus injecting 1 kilowatt power to the electrical grid. According to Copextel, installing photovoltaic solar systems requires essential conditions such as a ceiling surface (roof) or a 12,5 sqm concrete floor. Customers will be able (from Thursday) to go to the Electric Company to contract the connection to the National Electroenergetic System only in Havana in the first stage. Payment can be made in cash, electronically, or request a loan at a bank for the amount of CUP 55,000 (approximately $2,300). This is the first time such systems are marketed to the Cuban people in CUP.

Link To Recent Analysis

Cuba Suspends Tariffs And Fees For Non-Commercial (SME's Next?) Solar Systems. Another Opportunity For Biden-Harris Administration To Support U.S. Exporters And Florida Companies Should Benefit. July 30, 2021

Granma

Havana, Republic of Cuba

4 November 2021

Paneles solares, sombras donde debe dar el sol (+ Video)

La única fábrica de paneles solares que existe en Cuba aspira a estabilizar su producción y apoyar al país en la transformación de la matriz energética

El costo de las materias primas se ha reducido en los últimos años y la potencia de los paneles ha aumentado, lo que hace más eficiente el proceso productivo. Pinar del Río.-En una pared de la Empresa de Componentes Electrónicos Ernesto Che Guevara cuelgan todos los tipos de paneles solares fabricados en la industria en los últimos 20 años.

La colección abarca desde los pequeños módulos de cinco watts, que hoy parecen una reliquia, hasta los de 380 que se hacen por estos días; y constituye una suerte de memoria histórica de la producción que se ha modernizado con el paso del tiempo. Tanto es así que, aparte de ella, no hay mucho más que recuerde aquellos primeros años en que todo se hacía a mano, por decenas de obreros que soldaban, una a una, cada celda fotovoltaica, y quienes poco a poco han dado paso a las máquinas, en busca de eficiencia. María del Carmen Santalla, una de las fundadoras, recuerda que al principio todo era prácticamente artesanal. Entonces, la producción anual de paneles de la unidad empresarial de base (UEB) Energía Fotovoltaica, enclavada dentro de Componentes Electrónicos, apenas alcanzaba un megawatt pico (mwp) de generación. Pero los programas de electrificación rural emprendidos en el país y en otras naciones como Bolivia y Venezuela, en el marco de la Alianza Bolivariana para los Pueblos de Nuestra América (alba), le darían luz verde para su desarrollo.

Primero, la capacidad se incrementó a dos mwp. Luego, la introducción de una nueva línea, con un grado considerable de automatización, le permitió crecer a diez mwp en 2010. A principios de ese año, directivos de la entidad, ubicada en la ciudad de Pinar del Río, le aseguraron a Granma que el 65 % de los paneles ensamblados históricamente había tenido como destino la exportación, y que la demanda seguía creciendo continuamente. En julio de 2015, el Comandante de la Revolución Ramiro Valdés Menéndez destacó la importancia de la planta y de incrementar la utilización de la energía solar. «El sol no se acaba y está en todas partes. Hay pocas fuentes de energía con esas características. Por eso, esta es una industria con un gran horizonte», señaló. La UEB recién acababa de recibir una nueva inyección de equipos, que propiciaría el incremento de la producción. Sin embargo, ni la voluntad del país de transformar su matriz de generación, ni la disminución de los costos de las materias primas, ni el esfuerzo de Componentes Electrónicos para actualizar su tecnología han impedido los largos periodos de interrupción.

UNA INDUSTRIA EN STAND BY

En 2020, por ejemplo, la industria no recibió materia prima. De modo que se limitó a laborar en el primer trimestre del año con un remanente de los insumos que quedaron de 2019. Después, no le quedó más remedio que parar. Tras una larga pausa de 15 meses, la producción volvió a activarse a media máquina en junio pasado, pero solo con un turno de trabajo, de al menos dos posibles. «Ahora mismo hay compañeros nuestros reubicados en otros centros, que no se han podido incorporar», lamenta María del Carmen Santalla.

Aun cuando en los últimos dos años no ha habido un sector de la economía cubana ajeno a los efectos de la crisis generada por la covid-19, el colectivo de la planta pinareña asegura que sus problemas datan de mucho antes de la aparición del coronavirus. De hecho, en 2019, cuando el sars-cov-2 aún no había comenzado a hacer estragos, la fabricación de paneles vino a arrancar en el mes de agosto, precisamente por falta de insumos. «La historia de la fábrica siempre ha sido la misma respecto a las interrupciones», advierte José Antonio Páez, especialista del departamento de Tecnología y Calidad.

Félix Andrés Pérez, director de la UEB Energía Fotovoltaica, coincide en que las paradas provocadas por la inestabilidad en el suministro de las materias primas han sido un tema delicado, por el éxodo de trabajadores que implica. «Hay pasos de la línea en los que alcanzar un grado adecuado de especialización necesita tiempo. No se trata solamente de preparar un operario para manejar un equipo, sino de que logre el nivel que responda a la capacidad productiva de la planta y a la calidad que se requiere», dice. «Aquí las personas han estado reubicadas en los hospitales, en la campaña antivectorial, en labores agrícolas», cuenta María del Carmen Santalla. «Cada vez que comenzamos una producción, hay que preparar personal porque perdemos mucha gente».

KILOWATTS EN SACO ROTO

Aunque en varias ocasiones ha llegado a trabajar a plena capacidad, en tres turnos diarios de ocho horas, para la planta pinareña esa ha sido la excepción y no la regla. José Antonio Páez asegura que «la política del Estado es cambiar la matriz energética, para reducir la dependencia de los combustibles fósiles, pero no ha habido la solvencia económica requerida. «Hace algún tiempo se manejó aquí un proyecto para llegar a 50 MW anuales, que en cinco años hubiera tenido un impacto similar al de un generador térmico de la central Guiteras. Se hicieron los estudios, pero al final todo quedó ahí», rememora el especialista.

Ni siquiera la capacidad instalada en la industria se ha aprovechado de modo estable, a pesar de los resultados que arrojan los parques fotovoltaicos montados con los paneles ensamblados en ella. Yanet Páez Hernández, directora territorial de la Empresa de Fuentes Renovables de Energía, señala que las tres instalaciones con tecnología cubana que existen en la provincia (hay otras cinco de tecnología china) generaron en lo que va de año 6 123 MW, para un ahorro de 1 592 toneladas de combustible, y dejar de emitir a la atmósfera 4 898,4 toneladas de dióxido de carbono. Ante los problemas recurrentes, José Antonio Páez comenta que han tratado de sobrevivir a toda costa, que la industria se las ha arreglado para irse actualizando, a la par de las tendencias en el mundo y de los formatos de paneles más vendidos. «Es imposible estar siempre al nivel de los más modernos, pero intentamos insertarnos en los que más se fabrican, porque es al mismo tiempo la materia prima que más abunda y la menos costosa».

Siguiendo ese principio, Félix Andrés Pérez explica que la planta asumió en junio la producción de 5 000 módulos de 340 w, con los insumos de un donativo de la Unión Eléctrica, y está haciendo ahora los primeros 7 000 de un nuevo encargo, que debe llegar a las 27 000 unidades y dar garantía de trabajo hasta el primer trimestre de 2022. Para el director de la UEB, el encuentro del Presidente Miguel Díaz-Canel Bermúdez con científicos y expertos en el tema de las fuentes renovables de energía (FRE), durante la sesión más reciente del Consejo Nacional de Innovación, y la comparecencia del ministro de Energía y Minas, Liván Arronte Cruz, en la última jornada de la Asamblea Nacional, en la que afirmó que el país cuenta con una estrategia a largo plazo para incrementar la generación con las FRE y depender menos de los combustibles fósiles, constituyen una señal de esperanza. «Somos la única fábrica de paneles que existe en Cuba y tenemos más de 20 años de experiencia en su producción –dice–. Por tanto, podemos ayudar a concretar ese objetivo de transformar la matriz de generación eléctrica».

Prensa Latina News Agency

Havana, Republic of Cuba

4 November 2021

Solar panels, shadows where the sun should shine (+ Video)

The only solar panel factory that exists in Cuba aspires to stabilize its production and support the country in the transformation of the energy matrix The cost of raw materials has been reduced in recent years and the power of the panels has increased, which makes the production process more efficient. Pinar del Río.

On a wall of the Ernesto Che Guevara Electronic Components Company hang all the types of solar panels manufactured in the industry in the last 20 years. The collection ranges from the small five-watt modules, which today seem like a relic, to the 380-watt modules that are made these days; and it constitutes a kind of historical memory of production that has been modernized over time. So much so that, apart from her, there is not much else that recalls those first years when everything was done by hand, by dozens of workers who welded, one by one, each photovoltaic cell, and who little by little have given way to machines, in search of efficiency.

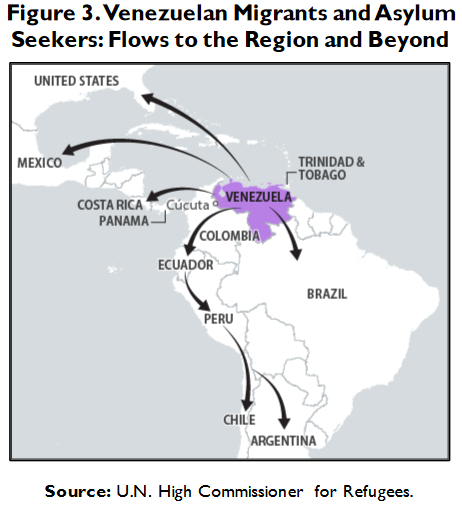

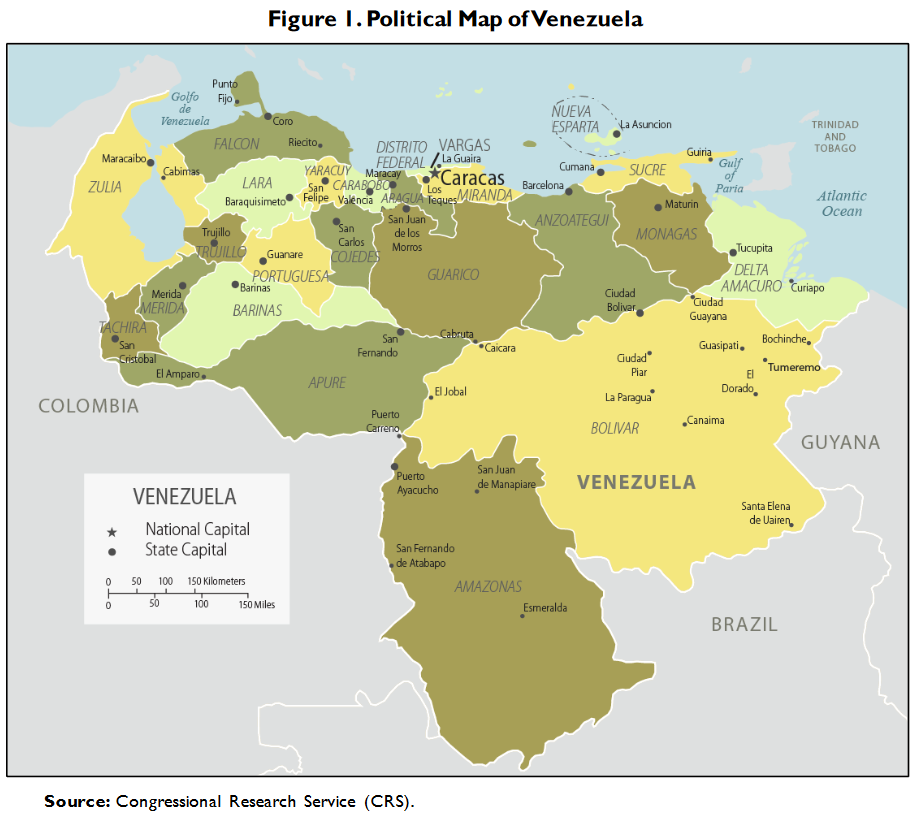

María del Carmen Santalla, one of the founders, remembers that at the beginning everything was practically handmade. At that time, the annual production of panels of the photovoltaic energy base business unit (UEB), located within Electronic Components, barely reached one megawatt peak (mwp) of generation. But the rural electrification programs undertaken in the country and in other nations such as Bolivia and Venezuela, within the framework of the Bolivarian Alliance for the Peoples of Our America (alba), would give it the green light for its development. First, the capacity was increased to two mwp.

Then the introduction of a new line, with a considerable degree of automation, allowed it to grow to ten mwp in 2010. At the beginning of that year, executives of the entity, located in the city of Pinar del Río, assured Granma that 65% of the panels assembled historically had been destined for export, and that the demand continued to grow continuously. In July 2015, the Commander of the Revolution Ramiro Valdés Menéndez highlighted the importance of the plant and of increasing the use of solar energy. «The sun does not end and it is everywhere. There are few energy sources with these characteristics. For this reason, this is an industry with a great horizon ”, he pointed out. The UEB had just received a new injection of equipment, which would lead to increased production. However, neither the will of the country to transform its generation matrix, nor the decrease in raw material costs, nor the effort of Electronic Components to update its technology have prevented long periods of interruption.

AN INDUSTRY IN STAND BY

In 2020, for example, the industry received no raw materials. So he limited himself to working in the first quarter of the year with a remnant of the supplies left over from 2019. Afterwards, he had no choice but to stop. After a long 15-month hiatus, production resumed at mid-machine last June, but only with one shift, out of at least two possible. "Right now there are colleagues of ours relocated to other centers, who have not been able to join," laments María del Carmen Santalla.

Even though in the last two years there has not been a sector of the Cuban economy oblivious to the effects of the crisis generated by covid-19, the collective of the Pinar del Río plant assures that its problems date from long before the appearance of the coronavirus. In fact, in 2019, when sars-cov-2 had not yet started to wreak havoc, panel manufacturing started in August, precisely due to a lack of supplies. "The history of the factory has always been the same with regard to interruptions", warns José Antonio Páez, specialist in the Department of Technology and Quality.

Félix Andrés Pérez, director of the UEB Energía Fotovoltaica, agrees that the stops caused by the instability in the supply of raw materials have been a sensitive issue, due to the exodus of workers that it implies. “There are steps along the line where it takes time to achieve a suitable degree of specialization. It is not just a matter of preparing an operator to handle a piece of equipment, but of achieving the level that responds to the productive capacity of the plant and to the quality that is required, "he says. "Here people have been relocated to hospitals, in the anti-vector campaign, in agricultural work," says María del Carmen Santalla. "Every time we start a production, we have to train staff because we lose a lot of people."

KILOWATTS IN BROKEN SACK

Although on several occasions it has come to work at full capacity, in three daily eight-hour shifts, for the Pinar del Río plant that has been the exception rather than the rule. José Antonio Páez assures that “the State's policy is to change the energy matrix, to reduce dependence on fossil fuels, but there has not been the required economic solvency. “Some time ago a project was managed here to reach 50 MW per year, which in five years would have had an impact similar to that of a thermal generator at the Guiteras plant. The studies were done, but in the end everything stayed there, ”recalls the specialist. Not even the installed capacity in the industry has been used in a stable way, despite the results produced by the photovoltaic parks assembled with the panels assembled in it.

Yanet Páez Hernández, territorial director of the Renewable Energy Sources Company, points out that the three facilities with Cuban technology that exist in the province (there are another five with Chinese technology) generated 6 123 MW so far this year, for savings of 1,592 tons of fuel, and stop emitting 4,898.4 tons of carbon dioxide into the atmosphere. Faced with recurring problems, José Antonio Páez comments that they have tried to survive at all costs, that the industry has managed to keep updating, along with world trends and the best-selling panel formats. "It is impossible to always be at the level of the most modern, but we try to insert ourselves in those that are manufactured the most, because it is at the same time the most abundant raw material and the least expensive".

Following this principle, Félix Andrés Pérez explains that in June the plant assumed the production of 5,000 340-watt modules, with inputs from a donation from the Unión Eléctrica, and is now making the first 7,000 of a new order, which must reach 27,000 units and guarantee work until the first quarter of 2022. For the director of the UEB, the meeting of President Miguel Díaz-Canel Bermúdez with scientists and experts on the subject of renewable energy sources (FRE), during the most recent session of the National Innovation Council, and the appearance of the Minister of Energía y Minas, Liván Arronte Cruz, in the last day of the National Assembly, in which he affirmed that the country has a long-term strategy to increase generation with FRE and depend less on fossil fuels, are a sign of hope. "We are the only panel factory that exists in Cuba and we have more than 20 years of experience in its production," he says. Therefore, we can help to achieve this objective of transforming the electricity generation matrix ”.